ATO Configuration Cycle In Order Management (Doc ID

844847.1)

In this Document

Purpose

Scope

Details

Setup Steps

Create items

Assign a sales price to the newly created items

Create stock for the purchased items (options) for a

sufficient test quantity

Create Bill Of Materials (BOMs)

Testflow steps

Sales Order creation

Configure the ATO model

Generate the Configured Item

Generate the WIP discrete job

Progress the WIP job

Complete the WIP job

Pick release the configured item line

Ship confirm the configured item line

Close the configured item line and invoicing process

References

APPLIES TO:

Oracle

Order Management - Version 11.5.8 to 12.1.1 [Release 11.5.8 to 12.1]

Information

in this document applies to any platform.

***

Checked for relevance 19-May-2013 ***

PURPOSE

This

document is intended to help users successfully setup organizations for the

purpose of Intercompany Invoicing through the Oracle Inventory Application.

The

purpose of this bulletin is to provide Oracle Customers with a good

understanding and the to build a test case for basic ATO Configurations

SCOPE

This

document helps the Support Engineers and Oracle Customers to understand the

setup steps with the relevant setup needed to create simple test case for ATO

Configurations.

Screen

shots of setups and test case in this note were done in an R11.5.10 instance on

an Oracle Internal Test Instance.

DETAILS

Setup Steps

Login

User

: OPERATIONS / WELCOME

Responsibility : Manufacturing and Distribution Manager

Create items

1.

To setup an ATO Model a few items are needed to get a BOM minimum skeleton.

Through this example, an ATO item (parent), an option class and 3 components

(purchased items) are needed.

=>

Navigate to Inventory -> Items -> Master Items

Select

organization :

V1 (Vision Operations)

=>Enter

Item Name and Description (with XX=your initials) :

Model item name : XX AtoModel M01

Description : XX AtoModel M01

=>

Go to Tools -> Copy From :

Apply the 'ATO Model' template

In

the Order Management tab, check that the Assemble to Order flag (ATO) is

checked.

In

the General Planning tab, check the Make or Buy flag to Make.

=>

Save the record, and assign the item to Organization M1.

2.

Similarly create Option Class item 'XX OCModel M01' using the 'ATO Option

Class' template, and the three purchased items like 'XX PurchItem1 M01' using

the Purchased item template. Assign them all to M1.

The

Option Class item has a WIP Supply Type as 'Phantom'.

Assign a sales price to the newly created items

Navigate

to Pricing -> Price List-> Price List Setup. Confirm it is active.

Create

a specific Price List (or query up 'Corporate' to add them to it) and go to the

List Lines zone.

Click

on the New button in the tool bar, enter the following information for each of

the created items, then click on Save

Product Context: Item

Product Attribute: Item Number

Product Value: XX AtoModel M01

Value: 15.5 (or any other value)

Leave other fields with default values

Create stock for the purchased items (options) for a

sufficient test quantity

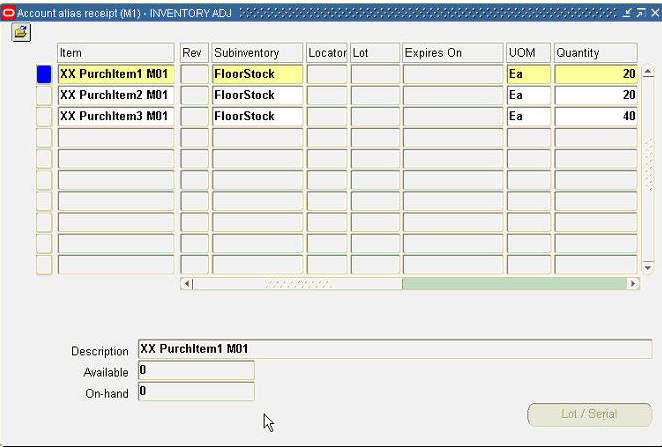

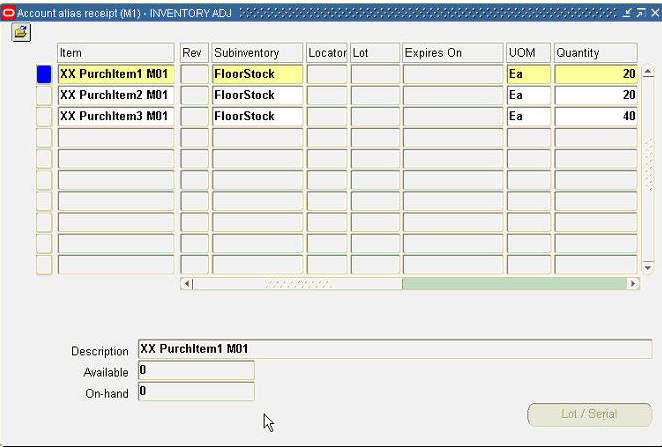

Navigate

to Inventory -> Transactions -> Miscellenaous Transactions

Select

organization : M1 (Seattle manufacturing)

Type : Account Alias Receipt (select whatever source)

Subinventory : FloorStock (for ex.)

Create Bill Of Materials (BOMs)

The

BOM to be built for the test case will be as simple as the following (Indented

BOM - final result) :

Using

a BOM Responsibility, you can either create the BOM in V1 Org. then copy it to

M1, or to create it in M1 Org. and make it a Common BOM.

The

BOM has to exist in both the OU (Validation Org.) and the Shipping Org.

Model

Routing has to be created first

Model

BOM to be then created, preferably starting for the lower level

=>

Navigate to BOM -> Routings -> Define

Enter the newly created ATO Model item name

Add operations 10 & 20 using (predefined) Standard Operations

Save

=>

Using a BOM Responsibility, navigate to BOM -> Bill Of Materials ->

Define

Enter the newly created Option Class item name

Add the components of the Option Class, here Purchased items 2 and 3 are

optional

Save

Then enter the Model item name

Add the option class and the Purchased item 1 (as mandatory items)

Set the purchased item 1 having a mandatory quantity of 2

Save

=>

Notice that the Option Class keeps a Supply Type as Phantom.

Testflow steps

The

flow describes the steps from the ATO Sales Order creation to its closure. Make

sure that the testing user has sufficient Shipping Role/Grants to process all

the WSH steps in Org. M1

Sales Order creation

Change

of Responsability to : Order Management Super User, Vision Operations (USA)

Navigate

to Orders,Returns -> Sales Order (or Order organizer) -> enter new S/O

Select M1 as the Warehouse (Others tab)

Go

to the Lines tab and enter your model item

Item : XX AtoModel M01

Enter the line quantity

Configure the ATO model

Click

on the Configurator button to open the CZ selector and to select the model

options

Notice

that

-

the item 'XX OCModel M01' has a red star in the model tree : this to indicate

that a component (at least) of the option class is mandatory

-

the Purchased item 1 does not appear as being mandatory and not an option

Select

the desired components

Click

on the 'done' button when finished, i.e. when the configuration is complete

=>

The cursor is back to the sales order entry form and the order can be booked as

the configuration is complete :

Generate the Configured Item

=>

The ATO model line workflow has now progressed to the 'Create configuration

eligible' activity.

From

the ATO model line, the configured (ATO item or 'star' item) is ready to be

created :

Select

Actions -> Progress Order

Click OK

=>

This creates the configured item on line 1.1..0 :

This

line WF is at 'Create Supply Order Eligible' activity :

Generate the WIP discrete job

From

the configured item line, the WIP discrete job is ready to be created :

Select

Actions -> Progress Order

Click

OK

=>

This launches a Concurrent Request process :

=>

The result of the request is seen in View requests : AutoCreate Final Assembly

Orders.

The

output shows the WIP Discrete Job Order number for the ATO item : 98704

=>

Place the cursor on the configured item line in S/O entry form, and you’ll

check that the Reserved Quantity = 2.

=>

The Job name can be checked from the S/O entry form by using the menu options :

.

Tools -> Scheduling -> Reservations Details

.

The WIP job order inherits the sales order quantity of the configured item.

Progress the WIP job

It

is necessary to progress the WIP discrete job up to completion in order to

fulfill the reserved sales order demand of the configured item line. Then the

configured item will have some stock to be pick released and shipped against

the sales order.

=>

Change to a Manufacturing/WIP responsibility to check the job number created in

unreleased status in Org. M1.

.

Navigate : WIP -> Discrete Jobs -> Discrete

.

Query the job number (or the configured item as the Assembly) : 98704

=>

Change its status to Released and save :

The

link with the Sales Order line is shown when clicking on the Sales Orders

button :

=>

The discrete job order is now ready to be progressed until final completion. To

do this, it's required to move the start quantity from the first routing

operation (Step Queue of Operation 10) to the last one (at To Move step of

Operation 20) :

Navigate

: WIP -> Move Transactions -> Move Transactions

.

Query the job name (or the Assembly)

.

Set the transacted quantity

.

Select the From/To in the Operations zone

.

Save the move transaction

Complete the WIP job

=>

As the full WIP job quantity has been transferred to the last step of the last

operation, it can be completed. This will create the stock of the configured

item, reserved for the particular S/O line.

.

To directly set the WIP job as completed, navigate to : WIP > Material

transactions > Completion Transactions.

.

Query the job number

.

Select the subinventory where the stock is placed

.

Set the completed quantity

.

Click the 'Done' button

=>

The WIP job order has now a 'complete' status and shows the completed quantity

:

Pick release the configured item line

Responsibility

: Order Management Super User, Vision Operations (USA)

=>

At this stage, the sales order line of the Configured item is at awaiting

shipping status :

=>

The Line is ready to be pick released.

Navigate

: Order Management -> Shipping -> Transactions

.

In the Lines/LPN tab, verify that the line status is Ready to Release

.

Select the Launch Pick Release option from the Actions menu

.

click on the Go button

.

This launches the pick release concurrent request for the delivery.

=>

The delivery is now ready to be ship confirmed.

Ship confirm the configured item line

Navigate

: Order Management -> Shipping -> Transactions

.

(Re)Query the Sales Order

.

In the Lines/LPN tab, verify that the status is Staged/Pick Released

.

Confirm the Shipped quantity = Picked quantity

.

Select the Delivery tab

.

Select the Ship Confirm option from the Actions menu

.

click on the Go button

.

Keep the Ship Entered Quantities radio button checked on the Ship Confirm form

.

Check the feedback message (ITS run)

.

When ITS has ran fine, the cursor is back to the delivery tab of the Shipping

Transactions form. The delivery is now at Closed status.

Close the configured item line and invoicing process

=>

When ITS has ran fine, the configured item line has Shipped status. The

delivery status can be retrieved from the sales order line through the Actions

-> Additional line details option.

=>

The configured item line workflow is now in fulfill deferred activity.

=>

But only the ATO model line will be invoiced and will progress to invoicing

activity when the WF background has ran :

=>

The Sales Order 16567 lines (only components marked as optional in BOM can be

shown on invoice in addition to the ATO model) are now in the autoinvoice

interface table, ready to be processed by Receivables :

This

completes the steps for the ATO Configurations test flow

Refer

to the Oracle Order Management User Guide and the Oracle Configure To Order

Implementation Guide for documentation on ATO Configurations (referred to in

this page as the User and Implementation Guides)

Reference :- Order Management Testcase Repository Library (Doc ID 743389.1)